Ukulungiswa kunye neempawu ze-polyurethane semi-rigid foam kwi-handrails zezithuthi ezisebenza kakuhle.

Indawo yokubeka ingalo ngaphakathi emotweni yinxalenye ebalulekileyo yekhabhathi, edlala indima yokutyhala nokutsala ucango nokubeka ingalo yomntu osemotweni. Kwimeko yengxakeko, xa imoto kunye ne-handrail zingqubana, i-polyurethane soft handrail kunye ne-PP eguquliweyo (i-polypropylene), i-ABS (i-polyacrylonitrile - i-butadiene - i-styrene) kunye nezinye ii-handrail zeplastiki eqinileyo, zinokubonelela ngokuqina okuhle kunye ne-buffer, ngaloo ndlela zinciphisa ukwenzakala. Ii-handrail ze-polyurethane soft foam zinokubonelela ngemvakalelo entle yesandla kunye nokuthungwa komphezulu omhle, ngaloo ndlela ziphucula intuthuzelo kunye nobuhle be-cockpit. Ke ngoko, ngophuhliso lweshishini leemoto kunye nokuphuculwa kweemfuno zabantu zezinto zangaphakathi, iingenelo ze-polyurethane soft foam kwii-handrail zezithuthi ziya zicaca ngakumbi nangakumbi.

Kukho iintlobo ezintathu zee-handrails ezithambileyo ze-polyurethane: i-foam ekwaziyo ukumelana nobushushu obuphezulu, i-foam eziziqwengayo kunye ne-foam eqina. Umphezulu wangaphandle wee-handrails ezikwaziyo ukumelana nobushushu obuphezulu ugqunywe lusu lwe-PVC (polyvinyl chloride), kwaye ingaphakathi liyi-polyurethane high relief foam. Inkxaso ye-foam ibuthathaka, amandla aphantsi, kwaye ukunamathelana phakathi kwe-foam kunye nolusu akwanelanga. I-handrails eziziqwengayo inomaleko wesikhumba oyintloko we-foam, ixabiso liphantsi, inqanaba eliphezulu lokudibanisa, kwaye isetyenziswa kakhulu kwizithuthi zorhwebo, kodwa kunzima ukuqwalasela amandla omphezulu kunye nentuthuzelo iyonke. I-armrest eqina igqunywe lusu lwe-PVC, ulusu lubonelela ngokuchukumisa okuhle kunye nenkangeleko, kwaye i-foam yangaphakathi eqina ivakalelwa kakuhle, ukumelana nempembelelo, ukufunxwa kwamandla kunye nokumelana nokwaluphala, ngoko ke isetyenziswa ngakumbi nangakumbi ekusebenziseni ingaphakathi lemoto yabakhweli.

Kule phepha, ifomula esisiseko ye-polyurethane semi-rigid foam yezandla zeemoto iyilwe, kwaye ukuphuculwa kwayo kufundwa ngale ndlela.

Icandelo lovavanyo

Izinto eziphambili zokwenza imveliso

I-polyol ye-Polyether A (ixabiso le-hydroxyl 30 ~ 40 mg/g), i-polyol ye-polymer B (ixabiso le-hydroxyl 25 ~ 30 mg/g): I-Wanhua Chemical Group Co., LTD. I-MDI eguquliweyo [i-diphenylmethane diisocyanate, w (NCO) yi-25% ~ 30%], i-composite catalyst, i-wetting dispersant (i-Agent 3), i-antioxidant A: I-Wanhua Chemical (Beijing) Co., LTD., i-Maitou, njl.njl.; I-wetting dispersant (i-Agent 1), i-wetting dispersant (i-Agent 2): I-Byke Chemical. Ezi zinto zingasentla zikumgangatho wezoshishino. Ulusu lwe-PVC lining: I-Changshu Ruihua.

Izixhobo eziphambili kunye nezixhobo

Umxube wesantya esiphezulu wohlobo lwe-Sdf-400, ibhalansi ye-elektroniki yohlobo lwe-AR3202CN, i-aluminium mold (10cm×10cm×1cm, 10cm×10cm×5cm), i-oven yombane ye-101-4AB, umatshini we-elektroniki we-universal tension we-KJ-1065, i-super thermostat yohlobo lwe-501A.

Ukulungiswa kwefomyula esisiseko kunye nesampulu

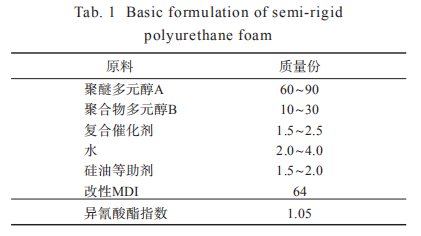

Indlela esisiseko yokwenza i-semi-rigid polyurethane foam iboniswe kwiTheyibhile 1.

Ukulungiswa kwesampulu yovavanyo lweepropati zoomatshini: i-polyether edityanisiweyo (izinto ezisetyenzisiweyo) yalungiswa ngokwefomula yoyilo, ixutywe ne-MDI eguquliweyo ngokwesilinganiso esithile, yaxutywa ngesixhobo sokuxuba esikhawulezayo (3000r/min) kangangemizuzwana emi-3 ~ 5, emva koko yathululelwa kwi-mold ehambelanayo kwi-foam, yaza yavula i-mold ngexesha elithile ukuze kufunyanwe isampuli ebunjiweyo ye-polyurethane foam eqinisiweyo.

Ukulungiswa kwesampulu yovavanyo lokusebenza kwe-bonding: umaleko wesikhumba se-PVC ubekwa kwi-die esezantsi ye-mold, kwaye i-polyether edibeneyo kunye ne-MDI eguquliweyo zixutywe ngokulinganayo, zivuselelwe sisixhobo sokuxuba esinesantya esiphezulu (3 000 r/min) kangangemizuzwana emi-3 ukuya kweyesi-5, emva koko zigalelwe kumphezulu wesikhumba, kwaye i-mold ivaliwe, kwaye i-polyurethane foam enesikhumba ibunjwe ngaphakathi kwexesha elithile.

Uvavanyo lokusebenza

Iimpawu zoomatshini: 40% CLD (ubulukhuni bokucinezela) ngokovavanyo oluqhelekileyo lwe-ISO-3386; Amandla okutsalwa kunye nokwandiswa ngexesha lokuqhekeka kuvavanywa ngokomgangatho we-ISO-1798; Amandla okukrazula avavanywa ngokomgangatho we-ISO-8067. Ukusebenza kokubopha: Umatshini wokutsalwa kwe-elektroniki usetyenziswa ukuxobula ulusu kunye ne-foam kwi-180° ngokomgangatho we-OEM.

Ukusebenza kokwaluphala: Vavanya ukulahleka kweempawu zoomatshini kunye neempawu zokubopha emva kweeyure ezingama-24 zokwaluphala kwi-120℃ ngokweqondo lobushushu eliqhelekileyo le-OEM.

Iziphumo neengxoxo

Ipropati yoomatshini

Ngokutshintsha umlinganiselo we-polyether polyol A kunye ne-polymer polyol B kwifomyula esisiseko, impembelelo yedosi ye-polyether eyahlukeneyo kwiipropati zoomatshini ze-polyurethane foam eqinisiweyo ihlolwe, njengoko kubonisiwe kwiTheyibhile 2.

Kunokubonwa kwiziphumo ezikwiTheyibhile 2 ukuba umlinganiselo we-polyether polyol A kwi-polyol B unefuthe elikhulu kwiimpawu zoomatshini ze-polyurethane foam. Xa umlinganiselo we-polyether polyol A kwi-polyol B usanda, ukunwebeka xa kuqhekeka kuyanda, ubunzima bokucinezela buyancipha ukuya kwinqanaba elithile, kwaye amandla okutsalwa kunye namandla okukrazula atshintsha kancinci. Ikhonkco le-molecular ye-polyurethane ikakhulu liqulathe i-soft segment kunye ne-hard segment, i-soft segment evela kwi-polyol kunye ne-hard segment evela kwi-carbamate bond. Kwelinye icala, ubunzima be-molecular kunye nexabiso le-hydroxyl yee-polyols ezimbini zahlukile, kwelinye icala, i-polymer polyol B yi-polyether polyol eguqulwe yi-acrylonitrile kunye ne-styrene, kwaye ukuqina kwecandelo le-chain kuphuculwe ngenxa yokubakho kwendandatho ye-benzene, ngelixa i-polymer polyol B iqulethe izinto ezincinci ze-molecular, ezonyusa ubulukhuni be-foam. Xa i-polyether polyol A ingama-80 amacandelo kwaye i-polymer polyol B ingama-10 amacandelo, iimpawu zoomatshini ezipheleleyo ze-foam zingcono.

Ipropati yokubopha

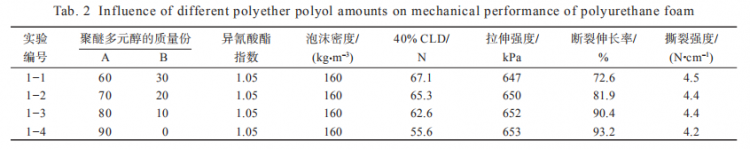

Njengemveliso enokucinezelwa rhoqo, i-handrail iya kunciphisa kakhulu intuthuzelo yeendawo ukuba i-foam kunye nesikhumba ziyaxobuka, ngoko ke ukusebenza kwe-polyurethane foam kunye nesikhumba kuyafuneka. Ngokusekelwe kolu phando lungentla, kongezwe ii-dispersants ezahlukeneyo zokumanzisa ukuvavanya iimpawu zokunamathela kwe-foam kunye nesikhumba. Iziphumo ziboniswe kwiTheyibhile 3.

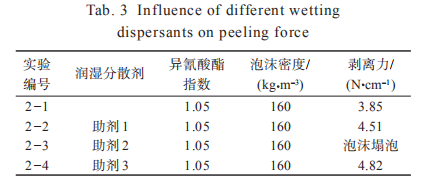

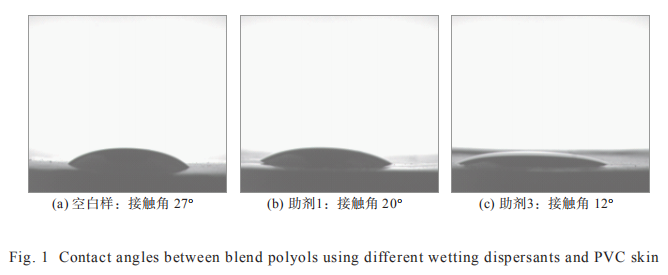

Kuyabonakala kwiTheyibhile 3 ukuba izinyibilikisi ezahlukeneyo zokumanzisa zinemiphumo ecacileyo kumandla okuxobuka phakathi kwefoam kunye nolusu: Ukuwa kwefoam kwenzeka emva kokusetyenziswa kwesithako 2, esinokubangelwa kukuvulwa kakhulu kwefoam emva kokongeza isithako 2; Emva kokusetyenziswa kwezithako 1 kunye no-3, amandla okuxobula esampuli engenanto anokwanda okuthile, kwaye amandla okuxobula esthako 1 aphezulu malunga ne-17% kunalawo esampuli engenanto, kwaye amandla okuxobula esthako 3 aphezulu malunga ne-25% kunalawo esampuli engenanto. Umahluko phakathi kwesithako 1 kunye nesithako 3 ubangelwa kakhulu ngumahluko ekumanzisweni kwezinto ezidityanisiweyo kumphezulu. Ngokubanzi, ukuvavanya ukumanziswa kolwelo kwi-solid, i-Angle yoqhagamshelwano yiparameter ebalulekileyo yokulinganisa ukumanziswa komphezulu. Ke ngoko, i-Angle yoqhagamshelwano phakathi kwezinto ezidityanisiweyo kunye nolusu emva kokongeza izinyibilikisi ezimbini ezimanzi ezingentla yavavanywa, kwaye iziphumo ziboniswe kuMfanekiso 1.

Kuyabonakala kuMfanekiso 1 ukuba i-Angle yoqhagamshelwano lwesampulu engenanto yeyona inkulu, eyi-27°, kwaye i-Angle yoqhagamshelwano lwe-arhente encedisayo 3 yeyona incinci, eyi-12° kuphela. Oku kubonisa ukuba ukusetyenziswa kwe-additive 3 kunokuphucula ukufuma kwezinto ezidityanisiweyo kunye nolusu ngokubanzi, kwaye kulula ukusasazeka kumphezulu wolusu, ngoko ke ukusetyenziswa kwe-additive 3 kunamandla amakhulu okuxobula.

Ipropati yokwaluphala

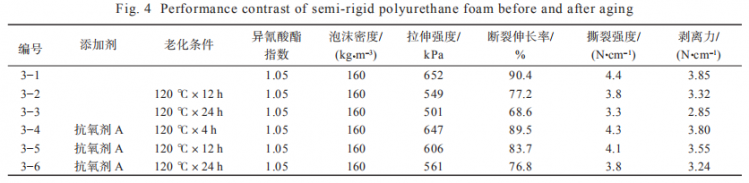

Iimveliso ze-handrail zicinezelwa emotweni, ubuninzi bokukhanya kwelanga buphezulu, kwaye ukusebenza kokwaluphala yenye indlela ebalulekileyo ekufuneka iqwalaselwe yi-polyurethane semi-rigid handrail foam. Ke ngoko, ukusebenza kokwaluphala kwefomyula esisiseko kwavavanywa kwaye kwenziwa uphando lokuphucula, kwaye iziphumo ziboniswe kwiTheyibhile 4.

Ngokuthelekisa idatha ekwiTheyibhile 4, kunokufunyaniswa ukuba iipropati zoomatshini kunye neepropati zokubopha zefomyula esisiseko ziyancipha kakhulu emva kokuguga kobushushu kwi-120℃: emva kokuguga iiyure ezili-12, ukulahleka kweepropati ezahlukeneyo ngaphandle koxinano (okufanayo ngezantsi) yi-13% ~ 16%; Ukulahleka kokusebenza kokuguga iiyure ezingama-24 yi-23% ~ 26%. Kuboniswa ukuba ipropati yokuguga kobushushu yefomyula esisiseko ayilunganga, kwaye ipropati yokuguga kobushushu yefomyula yokuqala inokuphuculwa ngokucacileyo ngokongeza udidi lwe-A lwe-antioxidant A kwifomyula. Phantsi kweemeko ezifanayo zovavanyo emva kokongezwa kwe-antioxidant A, ukulahleka kweepropati ezahlukeneyo emva kweeyure ezili-12 yayiyi-7% ~ 8%, kwaye ukulahleka kweepropati ezahlukeneyo emva kweeyure ezingama-24 yayiyi-13% ~ 16%. Ukwehla kweepropati zoomatshini kubangelwa ikakhulu luchungechunge lweempendulo zetyathanga ezibangelwa kukwaphuka kwebhondi yeekhemikhali kunye nee-free radicals ezisebenzayo ngexesha lenkqubo yokuguga kobushushu, okubangela utshintsho olusisiseko kwisakhiwo okanye iipropati zento yokuqala. Kwelinye icala, ukwehla kokusebenza kwe-bonding kubangelwa kukwehla kweempawu zoomatshini ze-foam ngokwayo, kwelinye icala, kuba ulusu lwe-PVC lunenani elikhulu lee-plasticizers, kwaye i-plasticizer iyafuduka iye kumphezulu ngexesha lenkqubo yokuguga kwe-oksijini eshushu. Ukongezwa kwee-antioxidants kunokuphucula iimpawu zayo zokuguga kwe-thermal, ikakhulu kuba ii-antioxidants zinokususa ii-free radicals ezisandula ukuveliswa, zilibazise okanye zithintele inkqubo ye-oxidation ye-polymer, ukuze kugcinwe iimpawu zokuqala ze-polymer.

Ukusebenza okubanzi

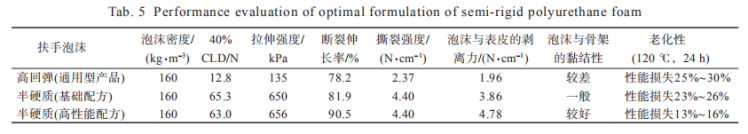

Ngokusekelwe kwiziphumo ezingentla, ifomyula efanelekileyo yenzelwe kwaye iimpawu zayo ezahlukeneyo zavavanywa. Ukusebenza kwefomyula kuthelekiswa noko kwefoam yesandla ye-polyurethane ephezulu ephindaphindayo. Iziphumo ziboniswe kwiTheyibhile 5.

Njengoko kunokubonwa kwiTheyibhile 5, ukusebenza kwefomyula ye-polyurethane foam efanelekileyo ene-semi-rigid kuneenzuzo ezithile kuneefomyula ezisisiseko kunye neziqhelekileyo, kwaye iyasebenza ngakumbi, kwaye ifanelekile ngakumbi ekusetyenzisweni kwee-handrails ezisebenza kakuhle.

Isiphelo

Ukulungisa ubungakanani be-polyether kunye nokukhetha i-dispersant emanzi efanelekileyo kunye ne-antioxidant kunokunika i-polyurethane foam eqinisiweyo iipropati ezilungileyo zoomatshini, iipropati ezilungileyo zokuguga kobushushu njl.njl. Ngokusekelwe ekusebenzeni kakuhle kwe-foam, le mveliso ye-polyurethane eqinisiweyo yeefowuni esebenza kakhulu ingasetyenziswa kwizinto ze-buffer zeemoto ezifana nee-handrails kunye neetafile zezixhobo.

Ixesha leposi: Julayi-25-2024